Cutting

DESIGN & MATERIALS SPECS

Commonly Cut Materials

Acrylics

Aluminum

Armor Plate (AR500; AR400; A36)

Brass

Bronze

Cast Iron

Carbon Fiber

Compound Metals

Copper

Copper/Tungsten Alloy

Foam

Granite

Graphite

Hard Steel

Inconel

Leather

Limestone

Linoleum

Manganese Steel

Mild Steel

Molybdenum

Mylar

Nickel Alloys

Nylon

Plexiglass

Polycarbonate

Polyethylene

Polymers

Reflective Materials

Stainless Steel

Stone

Tile

Titanium

Travertine

Tungsten

Check with us about other

man-made or natural materials,

or for cuts more than 5” thick.

|

|

|

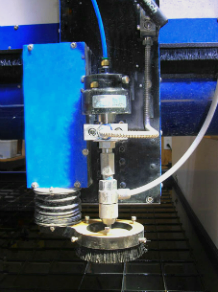

Advantages of Waterjet Cutting

Waterjet cutting is a technologically-advanced process that uses computer-controlled power abrasion to cut most natural and man-made materials. It uses ordinary tap water and semi-precious garnet sand in an environmentally friendly cutting process.

No HAZ (Heat Affected Zone)

Laser, plasma, and oxy-fuel cutting methods produce heat that can damage sensitive surfaces when pressure cutting. Waterjet's cold-cut system eliminates problems caused by heat.

No Shear Stress

Warping, or deformation caused by force, occurs with most pressure cutting processes. Carbon fiber, acrylic, and laminate materials require more effective cutting methods. Waterjet is the answer.

Unmatched Versatility

Envision Rapid Cutting uses a WardJet ZXA-613, with a single cutting head, two (2) axis capability and a gigantic cutting envelope.

We can handle panels or pieces up to 144” long by 72” wide. (12’x6’)

Most materials respond well to cuts up to 6 inches thick, often with no secondary finishing. Depending on the material and your purpose, we may be able to make cuts up to 10 inches. Check with us if you have a question about this.

Waterjet cutting allows much higher tolerances than other cutting methods. Normal kerfs (cutting widths) are .04 to .05 inches. Depending on the material, higher rates may be possible.

Our CAD/CAM software is one of the most versatile design programs in the world. It uses or converts most mainstream file types, including Autocad .dfx and .dwg – even scanned images. Check with us if you have a question about your design specs.

We cut from as few as one prototype to thousands of identical duplicates. We serve B2B customers, architects, contractors, designers, artists, and individuals with DIY projects.

Importantly, we offer incredibly fast turn-around for times when you need it yesterday.

Our customers achieve remarkable cost saving by reducing waste and maximizing material use. We can save you valuable time and expensive handling and labor costs.

Note: Envision Rapid Cutting is located in Norman, Oklahoma. Our low regional delivery fees can minimize freight costs to your job site, often saving you a bundle. We can also assist by helping you arrange delivery to any job site in Oklahoma, Texas, Kansas, Arkansas or the world.

ERC approaches every job as if it were our own. We partner with you from first design draft to project completion. By becoming an extension of your team, we can you assure the highest level of satisfaction.

For some processes there is no better way to cut than waterjet. For some, there is ONLY waterjet.

If you don’t explore Envision Rapid Cutting, you may never know… Call Gene today!

Depending on your working material, we can use either abrasive or nonabrasive cutting methods.

Contact us to discuss the needs of your particular project.

gene@envisionrapidcutting.com

(405) 831-2085